Revealing the Mysteries about Vacuum Electrical Connectors

Vacuum electronic feed-throughs are essential elements in multiple research and industrial applications in which maintaining a vacuum is essential. They offer a way to convey electrical signals or power into a vacuum chamber while not compromising the stability of the vacuum environment. Whether in laboratory laboratories, semiconductor fabrication, or vacuum processing, these feedthroughs play a key role in ensuring that processes can be performed successfully while keeping the atmospheric contaminants at bay.

Understanding what vacuum electrical feedthroughs are and how they operate can unlock a deeper appreciation for their importance. Essentially, they act as a portal, permitting electrical connections to go through the walls of vacuum chambers while stopping the escape of gases. Their configuration and materials are carefully chosen to endure the extreme conditions found in vacuum environments, making them a captivating topic for those curious in the convergence of electrical engineering and vacuum technology.

Comprehending Vacuum Connectors

Vacuum interfaces are crucial parts in many scientific and commercial applications where the continuity of a vacuum setting must be upheld while allowing power connections. They serve as a link between the external environment and sealed chambers, enabling the conveyance of electric signals and sometimes including gases without compromising the vacuum integrity. The design of these connectors ensures that they can withstand the pressure variations while stopping contaminants from getting into the vacuum space.

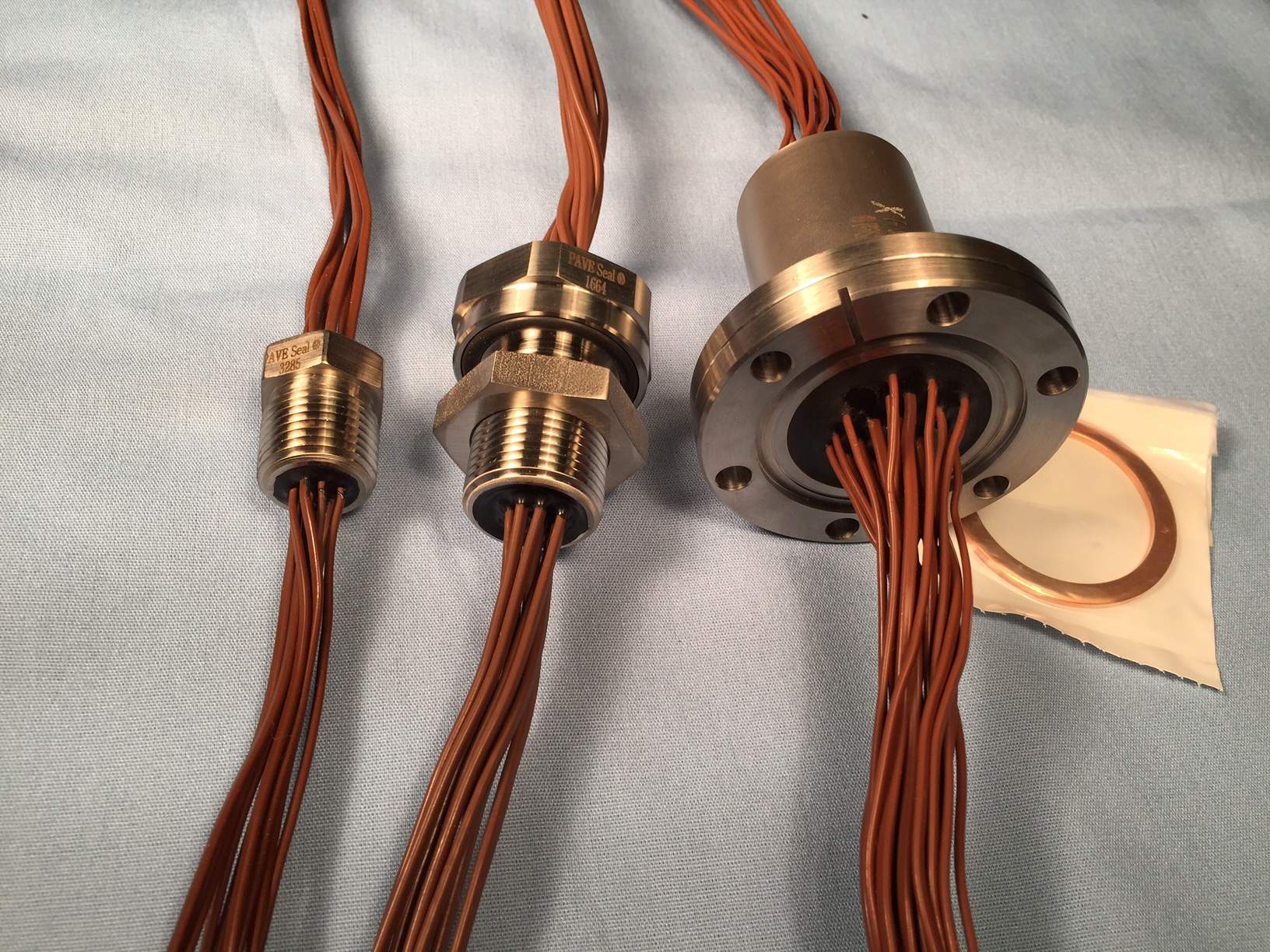

These devices are typically made with materials that possess both conductive properties and suitability for vacuum. Typical materials include ceramic composites, metal alloys, and glassy substances, which can be engineered to fit specific applications. The thoughtful selection of materials is essential because not all substances can tolerate the harsh conditions often encountered in high vacuum settings. Factors such as temperature variations, reactivity, and insulative properties must be considered to ensure longevity and dependability.

The performance of vacuum feedthroughs is critical in several areas, including semiconductor manufacturing, particle physics studies, and processing in vacuum. Their capability to maintain a steady electrical connection while upholding the vacuum environment helps boost the capabilities of systems like electron microscopes, laser systems, and accelerator systems. Comprehending the principles and applications of vacuum connectors is key to utilizing their potentials successfully in technological progress.

Implementations of Vacuum Feedthrough Technology

Vacuum feedthroughs play a crucial role in various industries where the requirement for sustaining a vacuum environment is essential. One notable application is in the fields of semiconductor manufacturing and investigation. In these environments, vacuum systems are used to create the necessary atmosphere for processes such as thin-film applications and etch techniques. Vacuum feedthroughs provide a means to connect electric signals to components within vacuum chambers without diminishing the integrity of the vacuum.

Another important use of vacuum feedthroughs is in scientific exploration, particularly in the field of physics and materials science. These devices allow researchers to engage with highly sensitive instruments and experimental setups that operate in a vacuum, enabling experiments involving electron microscopy, spectroscopy, and acceleration of particles. The dependability and stability of vacuum feedthroughs ensure that researchers can achieve exact measurements while shielding delicate systems from atmospheric contamination.

Furthermore, vacuum feedthroughs are necessary in the aeronautics and defense industries. They are typically used in satellite systems and propulsion systems, where high vacuum conditions are necessary for optimal performance. By facilitating electric connections without breaking the vacuum seal, these feedthroughs help in the operation of critical electronic systems, ensuring operability and reliability in extreme environments.

Picking the Right Vacuum Feed Through

When picking a vacuum feedthrough, it's crucial to consider the exact specifications of your project. Aspects such as vacuum level, heat, and the type of the electrical signals being transmitted will greatly affect your choice. For ultra-high vacuum environments, verify the feedthrough can keep its reliability under the expected environment. Additionally, think about the substances used in the fabrication of the feedthrough, as they need to be compatible with the vacuum setting to avoid outgassing.

The category of electrical interfaces required also holds a key factor in your choice. Various feedthrough designs support different types of conductors, including coax cables, multi-pin connectors, and ribbon connectors. It is essential to select a feedthrough that can support the electrical demands of your machinery while providing consistent insulation and shielding against environmental factors. Evaluate the risk for electromagnetic interference in your configuration, as some feedthrough designs offer better shielding than others.

Finally, think about the ease of setting up and service of the vacuum feedthrough. Some models may require specialized tools or approaches for installation, which could add to your overall initiative timeline and cost. Additionally, reflect on the future accessibility for replacement or renewal. Choosing a feedthrough that allows for more convenient maintenance can conserve time and resources in the future, guaranteeing that your setup stays operational without major downtime.